textile processes

and services

textile processes

and services

MARCU

marcu

Innovative textile processes and services

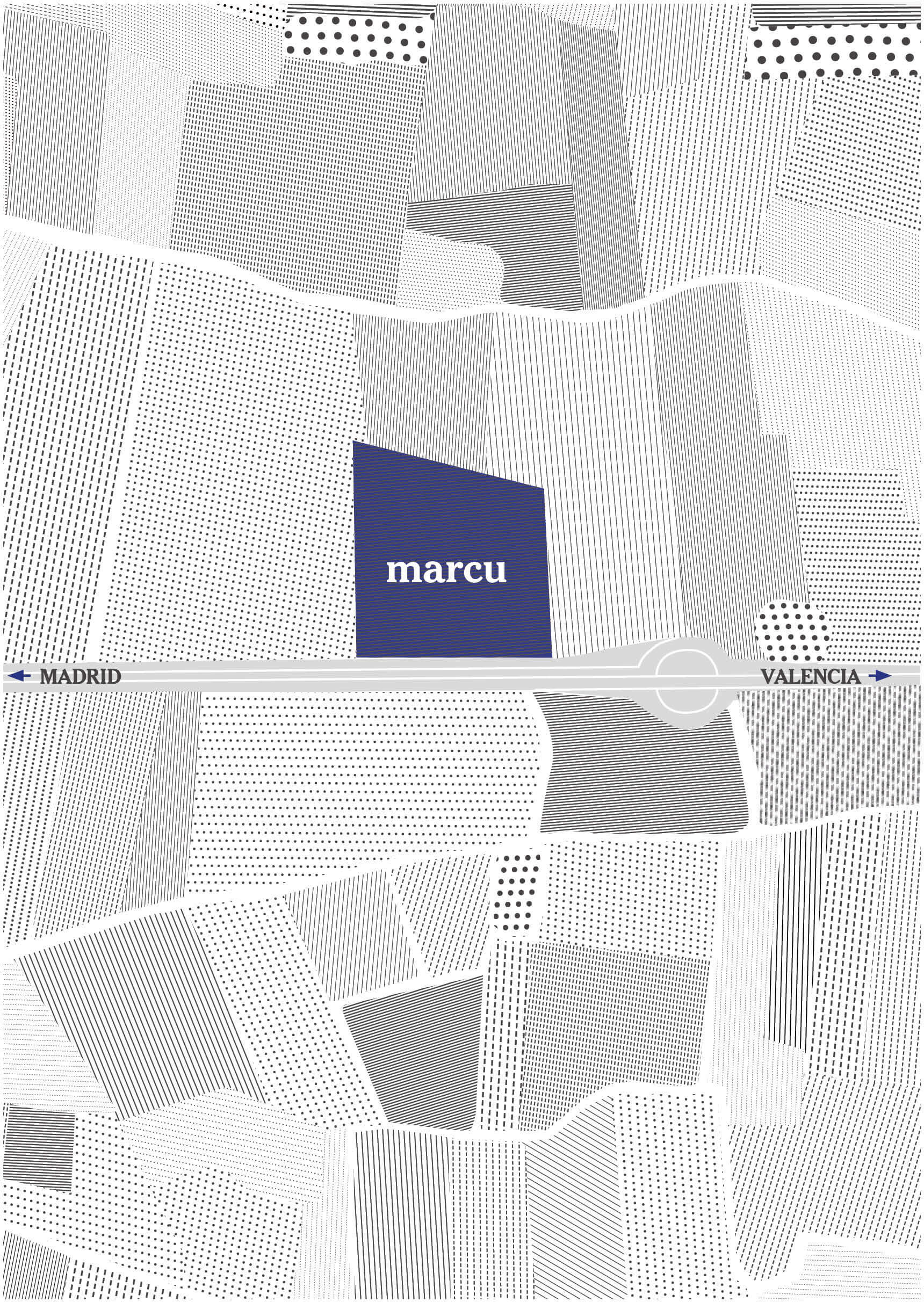

LOCATION

Prosertein Marcu

N310 road KM. 158,

16600 San Clemente, Cuenca

Tel/Fax +34 969 307 129

jcuenca@marcu.es

marcu

OUR

TEAM

From nine workers in 1998 to 36 workers today. An increase in the staff team in order to provide excellent service and honour the commitment of the brand to fulfil orders promptly. Always.

Punctuality and commitment, as well as excellence and reliability in each and every one of our in-house processes.

- Pattern design

- Cutting

- Tailoring

- Ironing

- Quality control

- Finishes

- Storage and stock control

The strongest and most renowned

in Europe.

FABRIC SECTION

- INTERTEX S.L.U.

- NEW JUNIOR S.A.

- ONE WAY TEX LDA.

- TAVEX EUROPE S.L. EVLOX

- RANDOM TEX S.L.

- TEJIDOS ROYO S.L.

- TEXTIL SANTANDERINA S.A.

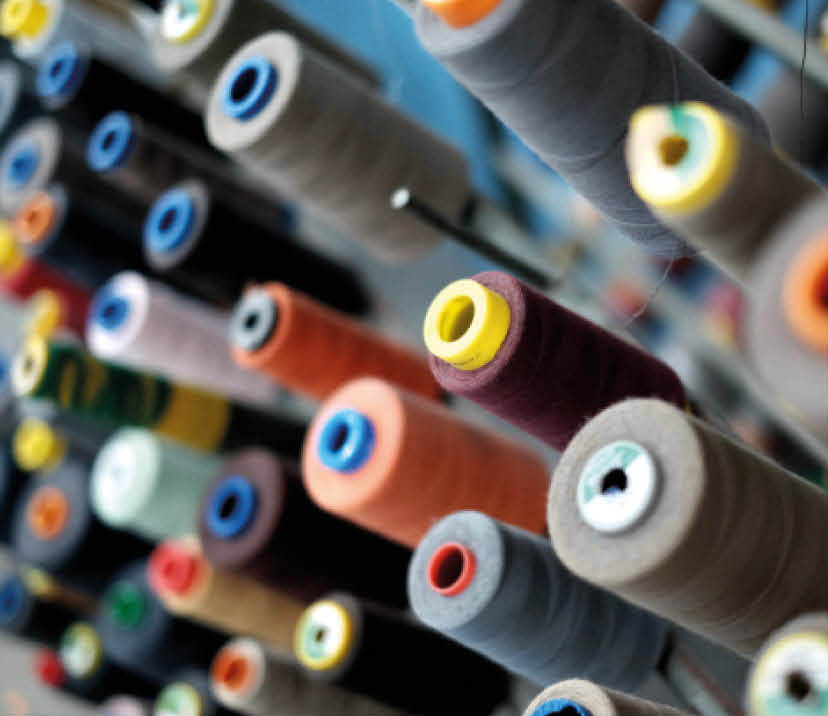

THREAD SECTION

- HILATURAS JORDA S.L.

- HILATEX DE MURO S.L.

- REALFIO TEXTEIS LDA.

- VALFIOS ARMAZEM DE FIOS TEXTIES LDA.

- AMANN SPAIN S.L.U.

BUTTONS

ZIPS AND LABELS

SECTION

- ANOSMAY BUTTONS S.L.

- CREMALLERA CATALANA S.A.

- HIJOS DE MARIANO DE P.BARRIOS S.A.

- YKK ESPAÑA S.A.

- ETIQUETAS MEDITERRANEO S.L.

LININGS

AND INTERFACING

SECTION

- FORTUNA TEXTIL S.L.

- MANLY S.A.

- PREMAN S.L.

REPLACEMENTS SECTION

- JUAN JOSE MIGUEL DE FRUTOS

- SUMINISTROS INDUSTRIALES S.L. RAPIDA

marcu

PARTNER

LAUNDRIES

And, among these, our collaborating laundries, the best and most important in Europe, specialists in the treatment of jeans, both denim and coloured jeans, who have comprehensive knowledge of the fabric and its possibilities, its life today and its life tomorrow; as well as our collaborating workshops for the manufacture of shirts.

Together, we make a great team that achieves the levels of excellence necessary to deliver a completely finished final product of the highest quality.

Innovative textile processes and services

Working hard to respect a close relationship with customers and suppliers ensures we can achieve lead times ranging from 30 days from the date of order confirmation up to a maximum of 50 days.

And never, in all our years of operation, has there been a delay. Never.

LEAD TIMES

30 days maximum

50 days maximum

marcu

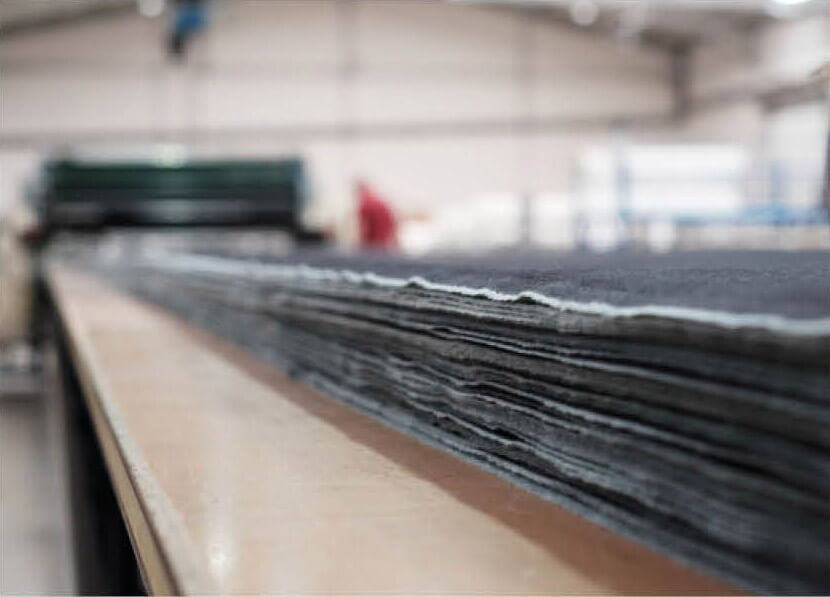

CRAFTSMANSHIP

AND INNOVATION

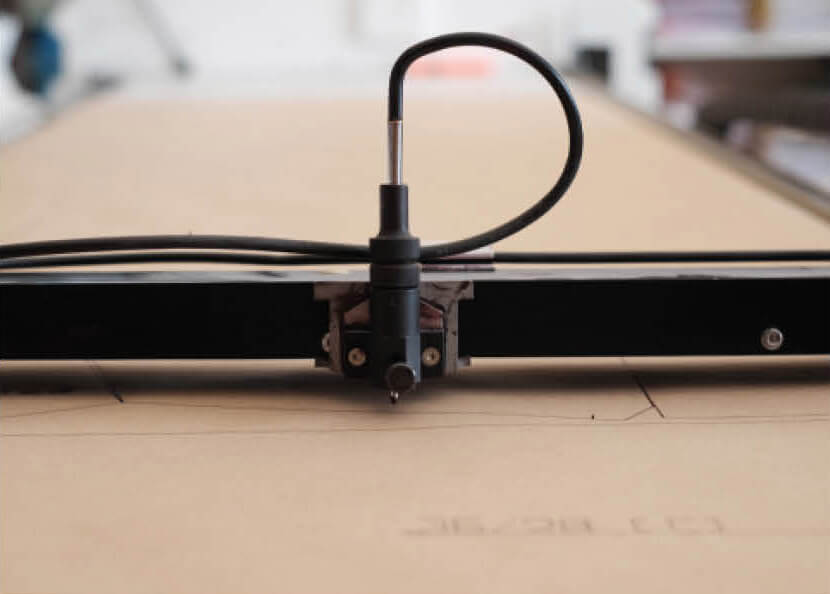

A combination of craftsmanship and innovation so that each operation has the appropriate machinery and processes. Machines equipped with the best technology but also old models that allow expert hands to work on details which the machines are not yet capable of handling.

Marcu therefore has a total of 78 sewing machines in its production chain, supported by a pool of replacements and operations ready to ensure that not a minute is wasted in the case of unforeseen events or changes of model.

SEWING MACHINES

replacements

model 43200 for

sewing hems”

Innovative textile processes and services

In addition, we have state-of-the-art cutting machinery as well as a plotter for marking, a programmed automatic carriage for extending, ironing machines, and a total of five vertical cutting machines.

And, to ensure that we are able to keep our word, we have two steam generators. The first of these supplies all our machinery and the second ensures that in case of breakdowns there is no delay, however brief.

PROGRAMMED

CARRIAGE

MACHINE

MARKING

GENERATORS

marcu

4,000 M2 OF

PREMISES

Premises of 4,000 square metres, with 2,000 m2 of warehouse, a manufacturing and ironing chain of 1,000 m2, and 1,000 m2 of offices that allow us to manufacture and deliver more than 1,000 garments a day completely finished, in addition to storing and handling a total of more than 600,000 garments a year.

m2 of premises

m2 of warehouse area

m2 for manufacturing and ironing

m2 of offices

Innovative textile processes and services

The work is carried out in close collaboration with our customers, for which we have technical offices and work rooms that allow them to design the patterns and create and produce their prototypes and samples.

And, from there, without losing a minute, we take care of the production.

Because being with the customer right there on the line helps us to be 100% effective and efficient, and that means offering our customers the same effectiveness and efficiency.

completely finished garments a day

600,000

garments a year

marcu

THE PLANET FIRST.

PEOPLE, TOO.

Innovative textile processes and services

It is a way of being and doing things that is based on the MADE IN SPAIN quality label. Because we think it is important to keep an old, added value industry in our territory, imprinting our commitment to a job well done on all our garments: controlling all the processes, always working closely with our customers and ensuring the quality of both the materials and the work carried out as a team.

A globally recognised label which is committed, first and foremost, to faithfully responding to consumers who know what they want.

N310 road KM. 158,

16600 San Clemente, Cuenca

Tel/Fax +34 969 307 129

jcuenca@marcu.es